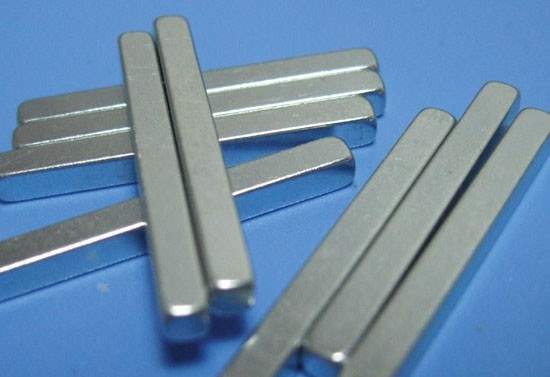

Neodymium Magnets

Arc type Disc type Ring type Rod type Block type Sphere type Neodymium Magnet manufacturer & supplier We are professional Neodymium Magnet manufacturer and supplier in China. We can produce Neodymium Magnet (NdFeB magnet) according to your requirements. More types of Neodymium Magnet (NdFeB magnet), Sintered Neodymium Magnet (NdFeB magnet), please contact us right now

Learn More

Arc type |

Disc type |

Ring type |

Rod type |

Block type |

Sphere type |

Samarium Cobalt Magnets

Build Your Custom Magnet Samarium Cobalt ( SmCo ) Magnets - Samarium cobalt magnets (SmCo) Samarium Cobalt magnets are a rare earth magnet material that offers the best value when comparing performance and size in high temperature or adverse environments. Samarium Cobalt magnets are higher in cost, but magnetically very strong and typically allow for dimensional reductions. A Samarium Cobalt rare earth magnet will offer excellent corrosion resistance and typically will not require a

Learn More

Ferrite Magnets

Ferrite Magnets are Sintered magnets (ceramic magnets) made from ferric oxide, a raw material which is abundant in supply, thus a steady flow of Ferrite magnets can be ensured at a reasonable price setting, in fact the lowest price among competing products in the market today. Due to its high-coercive property, there is a smaller chance of demagnetization, and they are suitable for being used in flat forms. The magnets are produced by pressing a fine-powder of ferric oxide in a mold and heat

Learn More

AlNiCo Magnets

Build Your Custom Magnet These magnets are based mainly on iron (Fe), aluminum (Al), nickel (Ni) and cobalt (Co). The magnets are fragile and not ductile. Therefore, after the raw metal is melted at high temperature and turned into an alloy, it is cast into a casting mold. These magnets are therefore also known as cast magnets. Al-Ni-Co magnets achieve high Br values and high temperature stability, readily cause low-temperature demagnetization and thermal demagnetization, achiev

Learn MoreDid You Know?

All of the pull force values we specify have been tested in our laboratory. We test these magnets in two different configurations. Case 1 is the maximum pull force generated between a single magnet and a thick, ground, flat steel plate. Case 2 is the maximum pull force generated with a single magnet sandwiched between two thick, ground, flat steel plates. Case 3 is the maximum pull force generated on a magnet attracted to another magnet of the same type.

The values are an average value for five samples of each magnet. A digital force gauge records the tensile force on the magnet. The plates are pulled apart until the magnet disconnects from one of the plates. The peak value is recorded as the "pull force". If using steel that is thinner, coated, or has an uneven or rusty surface, the effective pull force may be different than recorded in our lab.