Don’t see what you need? We can help.

Ask our experts about a custom magnet for your prototype, invention or specialty project.

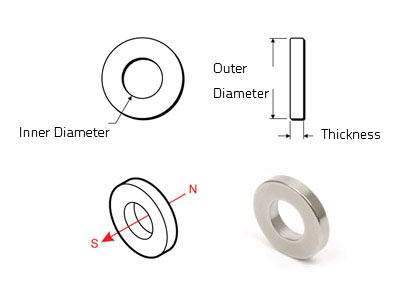

Strong Neodymium Ring Magnets N35, N38, N42, N45, N50 & N52. Neodymium Ring Magnets are widely used in such applications as holding, motors, consumer electronics, medical, sensors and speakers. Due to the high magnetic strength of a Rare Earth Magnet, it has replaced other magnetic materials in order to make a design smaller but achieve the same result.

Need a specific Neodymium Ring Magnet size and performance? If you require a specific size Rare Earth Neodymium Ring Magnet, please contact us.

Neodymium Ring Magnets

BUILD YOUR CUSTOM MAGNETS

Arc type |  Disc type |  Ring type |  Rod type |  Block type |  Sphere type |

Neodymium Ring Magnet manufacturer & supplier

Rare Earth Ring Magnets, also known as neodymium ring magnets, are often used in joinery and shop-fitting as they may be recessed and screwed into position. Although not as strong as Neodymium discs, the hole in centre of the ring magnet ensures great versatility.

This type of permanent magnet can be used in science projects or experiments, medical applications, cabinetry, water conditioning, loudspeakers and other commercial and industrial purposes. The higher permeance coefficient makes Neodymium ring magnets ideal for many applications.

Neodymium rings are one of the most popular shapes of rare earth magnets. TCM Magnetics manufactures a wide range of ring magnets in different sizes and with several different coatings such as Nickel, Zinc, Epoxy or Gold to prevent and reduce wear and corrosion.

|  |  |  |

|  |  |  |

|  |  |  |

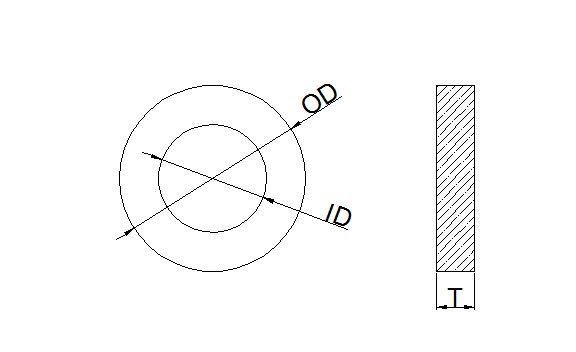

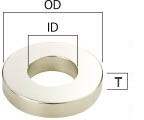

Ring Type

Measure:mm

| OD × ID × T | Shape | Surface magnetic flux density | magnetic absorption | ||

|---|---|---|---|---|---|

| kG | mT | kgf | N | ||

| 5φ × 2.4φ × 3 | Ring Magnets | 2.2 | 220 | 0.3 | 2.94 |

| 6φ × 3φ × 4 | Ring Magnets | 3.3 | 330 | 0.4 | 3.92 |

| 6.6φ × 2φ × 1.5 | Ring Magnets | 2.0 | 200 | 0.28 | 2.75 |

| 8φ × 2φ × 2.5 | Ring Magnets | 3.0 | 300 | 0.9 | 8.83 |

| 8φ × 4φ × 5 | Ring Magnets | 3.7 | 370 | 1.2 | 11.77 |

| 8.5φX5.5φ × 0.8 | Ring Magnets | 1.0 | 100 | 0.2 | 1.96 |

| 10φ × 5φ × 5 | Ring Magnets | 3.6 | 360 | 1.8 | 17.65 |

| 10φ × 6φ × 1 | Ring Magnets | 1.7 | 170 | 0.7 | 6.86 |

| 10φ × 6φ × 10 | Ring Magnets | 3.3 | 330 | 2.5 | 24.52 |

| 10.5φ × 7.6φ × 1 | Ring Magnets | 1.6 | 160 | 0.7 | 6.86 |

| 11φ × 4φ × 10 | Ring Magnets | 3.2 | 320 | 3.2 | 31.38 |

| 12φ × 6φ × 0.8 | Ring Magnets | 1.6 | 160 | 0.7 | 6.86 |

| 12φ × 7φ × 6 | Ring Magnets | 3.6 | 360 | 2.2 | 21.57 |

| 13.5φ × 5φ × 2 | Ring Magnets | 2.2 | 220 | 1.0 | 9.81 |

| 14φ × 9φ × 4 | Ring Magnets | 3.0 | 300 | 3.0 | 29.42 |

| OD × ID × T | Shape | Surface magnetic flux × density | magnetic absorption | ||

|---|---|---|---|---|---|

| kG | mT | kgf | N | ||

| 14.2φ × 10φ × 2 | Ring Magnets | 3.0 | 300 | 2.1 | 20.59 |

| 17φ X8.8φX1.25 | Ring Magnets | 1.8 | 180 | 1.0 | 9.81 |

| 18φ × 7φ × 6 | Ring Magnets | 3.6 | 360 | 5.5 | 53.94 |

| 19φ × 6.5φ × 10 | Ring Magnets | 4.5 | 450 | 8.4 | 82.38 |

| 23φ × 8φ × 3.5 | Ring Magnets | 3.0 | 300 | 3.5 | 34.32 |

| 23φ × 8φ × 14 | Ring Magnets | 4.2 | 420 | 12.0 | 117.68 |

| 23φ × 13φ × 1 | Ring Magnets | 1.3 | 130 | 1.8 | 17.65 |

| 25φ × 7φ × 6 | Ring Magnets | 3.6 | 360 | 7.3 | 71.59 |

| 26φ × 20φ × 6 | Ring Magnets | 3.5 | 350 | 5.5 | 53.94 |

| 31.2φX18.2φ × 1 | Ring Magnets | 1.2 | 120 | 3.2 | 31.38 |

| 39φ × 19φ × 7 | Ring Magnets | 3.5 | 350 | 20.0 | 196.13 |

| 59φ × 19φ × 10 | Ring Magnets | 4.5 | 450 | 45.0 | 441.30 |

| 70φ × 32φ × 15 | Ring Magnets | 4.5 | 450 | 50.0 | 490.33 |

| 76φ × 42φ × 6 | Ring Magnets | 3.5 | 350 | 55.0 | 539.37 |

| 98φ × 58φ × 10 | Ring Magnets | 4.0 | 400 | 65.0 | 637.43 |

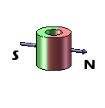

Magnetization Direction

Axial |  Diametrical |

Engineering drawing is important and necessary for ring shaped magnets. To avoid any misunderstanding of the dimensions and positions, please provide a clear drawing with detailed specifications, tolerance and additional requirements if any.

We list some drawings of common types of neodymium magnet ring as follows for your information.

Surface treatmen

For iron component (about 66%), it is easy disadvantages oxidizing power is strong rust there often (neodymium magnet) Nd-Fe-B sintered magnet. Surface treatment that a mandatory essential to prevent it, there is a method using various materials in it. To determine the material of plating depending on the environment used is neodymium.

| Pctures |  |  |  |  |  |  |

| Coating | Zinc | Nickel | Gold | Silver | Epoxy | Parylene |

| Thickness | 7-15um | 15-21um | 16-23um | 16-23um | 20-38um | 10-15um |

| Salt spray test | 12 hours | 24 hours | 36 hours | 24 hours | 48 hours | 48 hours |

Certificate