Don’t see what you need? We can help.

Ask our experts about a custom magnet for your prototype, invention or specialty project.

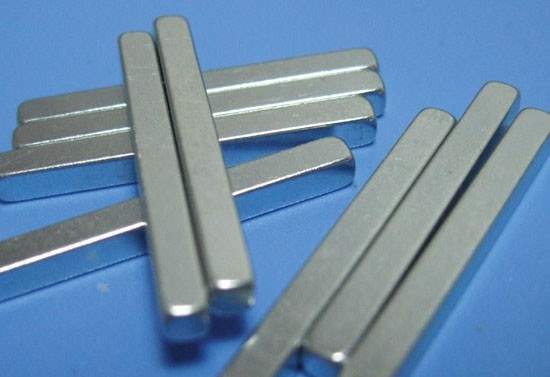

Neodymium Disc magnet are widely used as consumer electronics magnets, speaker magnets, sensor magnets, holding magnets, and many other applications.

Neodymium Disc Magnets, Neodymium Circular Disc Magnets

BUILD YOUR CUSTOM MAGNETS

Arc type |  Disc type |  Ring type |  Rod type |  Block type |  Sphere type |

Neodymium Disc Magnet manufacturer & supplier

Rare Earth Disc Magnets, also called neodymium disc magnets, are the perfect marriage of small size and maximum power or strength.

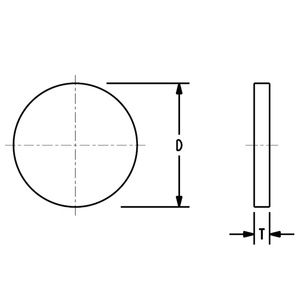

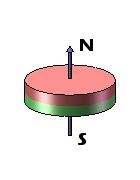

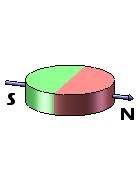

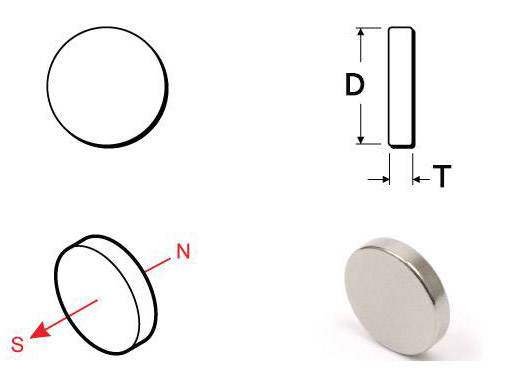

The neodymium disc magnets are the disc magnets made from neodymium magnetic material, it also called disc neodymium magnets, the disc is the most common shape for neodymium magnets, disc neodymium magnet looks round and flat which expressed by diameter and thickness. Mostly magnetized through thickness, that is axially magnetized.

With a diameter greater than the thickness, our neodymium disc magnets provide a very strong magnetic field and high coercivity. Excellent value for money ensures that Neodymium discs are among the most widely used commercially available magnets.

Please contact our sales team if you require more information about our neodymium disc magnets.

|  |  |  |

|  |  |  |

|  |  |  |

DIsc Type (Round Type)

Measure:mm

| OD × H | Shape | Surface magnetic flux density | magnetic absorption | ||

|---|---|---|---|---|---|

| kG | mT | kgf | N | ||

| 10φ × 3 | Disc Magnets | 3.5 | 350 | 2.0 | 19.61 |

| 10φ × 4 | Disc Magnets | 3.8 | 380 | 2.4 | 23.54 |

| 10φ × 5 | Disc Magnets | 4.2 | 420 | 2.6 | 25.50 |

| 10φ × 10 | Disc Magnets | 4.8 | 480 | 3.65 | 35.79 |

| 12φ × 1.3 | Disc Magnets | 2.0 | 200 | 1.45 | 14.22 |

| 12.5φ × 1.5 | Disc Magnets | 2.0 | 200 | 1.8 | 17.65 |

| 12.5φ × 2 | Disc Magnets | 2.0 | 200 | 1.9 | 18.63 |

| 13φ × 10 | Disc Magnets | 4.8 | 480 | 6.1 | 59.82 |

| 13φ × 20 | Disc Magnets | 5.5 | 550 | 9.5 | 93.16 |

| 14φ × 10 | Disc Magnets | 4.5 | 450 | 6.4 | 62.76 |

| 15φ × 1.5 | Disc Magnets | 1.8 | 180 | 1.1 | 10.79 |

| 15φ × 1.7 | Disc Magnets | 2.0 | 200 | 1.3 | 12.75 |

| 15φ × 3 | Disc Magnets | 3.2 | 320 | 3.7 | 36.28 |

| 15φ × 4 | Disc Magnets | 3.3 | 330 | 4.0 | 39.23 |

| 15φ × 5 | Disc Magnets | 3.3 | 330 | 4.5 | 44.13 |

| 15φ × 10 | Disc Magnets | 4.2 | 420 | 6.8 | 66.69 |

| 16φ × 10 | Disc Magnets | 4.2 | 420 | 7.2 | 70.61 |

| 17.9φ × 2.5 | Disc Magnets | 2.7 | 270 | 2.5 | 24.52 |

| 19φ × 10 | Disc Magnets | 4.0 | 400 | 9.8 | 96.11 |

| 20φ × 5 | Disc Magnets | 2.8 | 280 | 6.3 | 61.78 |

| 21φ × 4.6 | Disc Magnets | 3.2 | 320 | 7.0 | 68.65 |

| 22φ × 10 | Disc Magnets | 4.5 | 450 | 15.3 | 150.04 |

| 23.5φ × 3.4 | Disc Magnets | 2.0 | 200 | 4.0 | 39.23 |

| 23.5φ × 4.5 | Disc Magnets | 2.2 | 220 | 4.8 | 47.07 |

| 23.5φ × 5 | Disc Magnets | 2.4 | 240 | 5.6 | 54.92 |

| 24φ × 20 | Disc Magnets | 5.0 | 500 | 40.0 | 392.27 |

| 25φ × 3.4 | Disc Magnets | 1.8 | 180 | 4.2 | 41.19 |

| 25φ × 5 | Disc Magnets | 2.5 | 250 | 7.5 | 73.55 |

| 25φ × 6 | Disc Magnets | 3.0 | 300 | 8.0 | 78.45 |

| 25φ × 9.8 | Disc Magnets | 3.5 | 350 | 14.0 | 137.29 |

| 30φ × 15 | Disc Magnets | 5.0 | 500 | 22.0 | 215.75 |

| 32φ × 10.5 | Disc Magnets | 4.0 | 400 | 26.0 | 254.97 |

| 40φ × 10 | Disc Magnets | 3.8 | 380 | 35.0 | 343.23 |

| 50φ × 20 | Disc Magnets | 5.1 | 510 | 53.0 | 519.75 |

| 100φ × 15 | Disc Magnets | 3.7 | 370 | 75.0 | 735.50 |

Magnetization Direction

Axial |  Diametrical |

Engineering drawing is important and necessary for disc shaped magnets. To avoid any misunderstanding of the dimensions and positions, please provide a clear drawing with detailed specifications, tolerance and additional requirements if any.

We list some drawings of common types of neodymium magnet disc as follows for your information.

Surface treatmen

For iron component (about 66%), it is easy disadvantages oxidizing power is strong rust there often (neodymium magnet) Nd-Fe-B sintered magnet. Surface treatment that a mandatory essential to prevent it, there is a method using various materials in it. To determine the material of plating depending on the environment used is neodymium.

| Pctures |  |  |  |  |  |  |

| Coating | Zinc | Nickel | Gold | Silver | Epoxy | Parylene |

| Thickness | 7-15um | 15-21um | 16-23um | 16-23um | 20-38um | 10-15um |

| Salt spray test | 12 hours | 24 hours | 36 hours | 24 hours | 48 hours | 48 hours |

Certificate